In addition to being titanium stabilized, stainless steel 321/321H plates and sheets offer good mechanical properties and are extremely durable. In the range of temperatures where the stainless steel is exposed to chromium carbide, it is exceptionally corrosion resistant and also very resistant to intergranular corrosion. Furthermore, they possess a high creep and stress rupture properties compared to other alloys. Additionally, stainless steel 321/321H plates exhibit excellent low temperature toughness as well as a high level of strength. A 321H plate is an aluminum plate which can also be used in diluted organic acids at medium temperatures. It also has other features such as high tensile strength, durability, precise design, and many more, that contribute to its success.

In addition to the excellent resistance to intergranular corrosion that alloy 321 (UNS S32100) provides as a key advantage following exposure to temperatures in the chromium carbide precipitation range of 800 to 1500°F (427 to 816°C), it is also a stabilized stainless steel plate. It is added to alloy 321 stainless steel plates that is made of titanium to prevent the formation of chromium carbides.

In addition to its excellent mechanical properties, alloy 321 stainless steel plate is also suitable for high temperatures. In addition to offering a higher creep and stress rupture resistance than Alloy 304 and, particularly, Alloy 304L, alloy 321 stainless steel plate may be suitable for exposures involving sensitization and intergranular corrosion.

Specification-

- The standard specifications are ASTM A182/A240, ASME/ANSI B16.47 A/B series/B16.5, EN1092, DIN, BS4504, BA10, and ASME SA240/182.

In terms of dimensions, the product dimensions are found in EN, ANSI, ASME, API, JIS, DIN, ASTM, BS, etc.

There is a wide range of sizes available for the product, ranging from 12″ to 48″.

- Flanges are available in PN64, PN6, PN10, PN25, PN40, 2500#, 900#, 600#, 150#, and 300# pressures and classes as well as grades, which are PN64, PN6, PN10, PN25, PN40.

A wide range of face types are available for this product including ring type joints, raised faces, as well as flat rates.

Testing-

Tests to verify the quality of the item are conducted in various effective ways, such as:

- Test for pitting resistance

- Tests for intergranular corrosion

- Tests for flattening and flaring

- Tests at the macro and micro levels

- Tests on chemical and mechanical properties

- Tests of radiography

- Tests of hydrostatic pressure

ASTM A182 ss321 / 321H Standard Specification for Stainless Steel Industrial Flanges

The specifications are ASTM A182 / A240 and ASME SA182 / SA240

The dimensions can be found in ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

ANSI flanges, ASME flanges, BS flanges, DIN flanges, EN flanges are available.

The size ranges from 1/2″ (15 NB) to 48″ (1200 NB).

There are 7 types of classes / pressures – 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64#.

Types of flange faces are flat face (FF), raised face (RF), and ring type joint (RTJ).

General Properties

The alloy 321 (UNS S32100) has very good corrosion resistance due to its titanium stabilized austenitic structure. Having been exposed to temperatures in the chromium carbide precipitation range of 800 to 1500°F (427 to 816°C) it has excellent resistance to intergranular corrosion. This alloy exhibits excellent resistance to oxidation up to 1500°F (816°C) and has higher creep and stress rupture properties than alloys 304 and 304L, as well as being more resistant to corrosion at low temperatures.

The 321H stainless steel plate (UNS S 32109) has a higher carbon content (0.04 – 0.10). Due to its increased creep resistance and strength at temperatures over 1000oF (537°C), it is able to be dual certified in most instances.

There are various advantages of stainless Stainless strructures steel plate alloy 321 ss plate cannot be hardened by heat treatment, it can only be hardened by cold working. It can be welded and processed by standard fabrication practices.

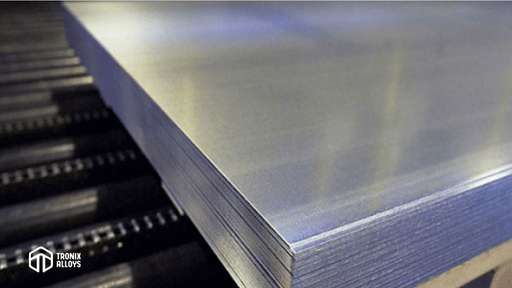

Types of 321/321H SS Sheets & Plates

- Polished 321 stainless steel plates

- Polished SS 321H plates

- Plates made of 321 SS polished

- Polished stainless steel plates 321H

- Polished SS UNS S32100 plates

- Polished SS WERKSTOFF NR. 1.4541

- Plates made of stainless steel 321 that have been hot rolled

- Hot Rolled SS 321H Plates

- Plates made of 321 stainless steel hot rolled

- Hot rolled stainless steel plates 321H

- Stainless steel hot rolled plates UNS S32100

- Plates hot rolled from SS WERKSTOFF NR. 1.4541

- Cold Rolled Plates in Stainless Steel 321H

- Cold rolled SS 321 plates

- Cold rolled SS 321H plates

- Cold rolled stainless steel plates 321

- Cold rolled stainless steel plates UNS S32100

- Cold Rolled Plates for Stainless Steel Werkstoff No. 1.4541

The stainless steel plates and sheets that are available are used in a wide variety of industrial applications that offer excellent performance for a variety of reasons. There are various applications of SS 321/321H Sheets & Plates, including power generation plants, offshore oil drilling refineries, gas processing industries, specialties chemicals, pharmaceuticals, pharmaceutical equipment, chemical equipment, heat exchangers, pulp and paper industry, and a wide variety of others.

Size of SS 321 / 321H Sheet

- Plate ASTM A240 321H 0.5-6.4 mm cold rolled

- 3.0–10.0 mm hot rolled SS A240 321 plate

- Stainless Steel Sheet 321H: 0.01~200mm

-